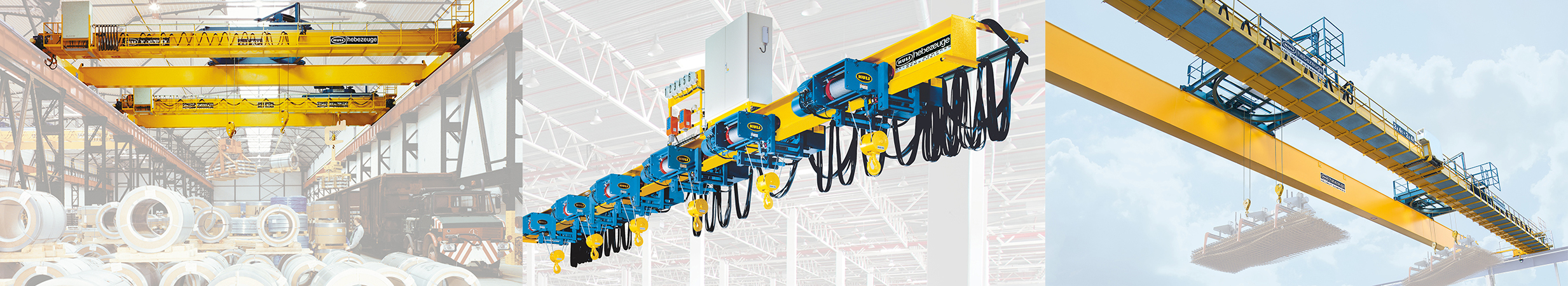

The All-Rounder Double Girder Bridge Crane with two rotating crabs

It is about 53 tons heavy and yellow. It carries loads up to 16 tons and has a span of 40 meters. In February 2017 it was delivered from Remscheid to a customer next to Cologne. The bridge crane was designed and manufactured by KULI Hebezeuge - Helmut Kempkes GmbH, based in Remscheid.

KULI Hebezeuge - Helmut Kempkes GmbH manufactures, among other things, electric wire rope hoists with a load capacity of 1 to 200 tons. These hoists are used in various crane and conveyor systems. Complete single- and double-girder cranes, suspension cranes, console- and gantry cranes are part of our scope of supply as well. Providing additional components, e.g. magnetic systems, grippers and vacuum devices complete our spectrum. We also supply electric chain hoists for loads up to 5 tons. They are mainly used for maintenance purposes within industrial and craft trades.

A real specialty is the manufacture, supply and assembly of bridge- and gantry cranes with rotating crabs. These are manufactured as double girder cranes with spans of up to approx. 70 meters.

The above bridge crane with a total capacity of 16 tons is used, among other things, for the handling of structural steel mats and reinforcing cages with a length of up to 25 meters. It runs on a newly constructed outdoor railway with a total length of 73 meters and a span of 40 meters.

All components are produced in our two production facilities in Remscheid, in particular, steel construction, control engineering, electrical installation, the manufacture of electric wire rope hoists and wheel bogies. Components such as the motors, gearboxes and rope drums are parts from our modular system. These individual parts are manufactured in a controlled manner and assembled according to their requirements for the particular application. This procedure offers the user the decisive advantage that he can count on the shortest delivery times even in the case of spare parts. Every operator of a crane will appreciate this.

The special feature of this crane is that two rotating crabs with two 4 ton hoists each are used. These hoists can be controlled individually, together and for one or both crabs. With the choice of grippers or the individual operation with hooks, the most diverse transport tasks can be realized, and the materials can be optimally positioned with a total rotation angle of 240 °.

Together with the customer, the requirements were analyzed for this transport task, with the aim of being able to use a specially adapted crane for the fast and safe transport of the materials. A further point was the configuration in terms of operability and maintenance.

Thus, the crane was equipped with frequency converters in long and cross travel as well as in the turntables. This allows a calm and fast transport of the suspended load. The travel speeds were set at a specific speed of up to 32 m / min during the cross- and up to 63 m / min during the long travel. By means of a radio remote control in belly type with 3 master switches and 12 additional selection options, all movements can be performed with highest accuracy. A second radio remote control ensures the permanent availability.

The crane has a maintenance walkway along one of the 40-meter-long girders as well as fully accessible turntables. The control cabinets with air-conditioning have been service-friendly installed on the walkway and on the rotating crabs.

The two girders each with a length of 40 meters and the two rotating crabs with an over-width of 4.5 meters reached a total transport length of 110 meters.

In the meantime, the assembly was completed by our KULI service personnel and the crane was released for operation in due time after a successful acceptance test.